Trusted company that deals in quality-made products

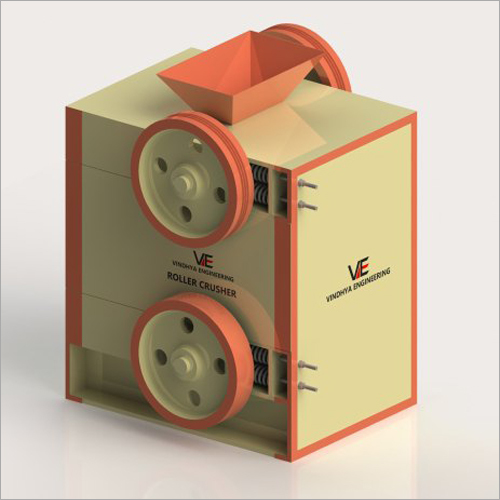

Double Roll Crusher

1500000.00 INR/Unit

Product Details:

- Product Type Stone Crusher

- General Use Stone

- Material Mild Steel

- Capacity 25 T/hr

- Computerized Yes

- Automatic Yes

- Dimension (L*W*H) 400 x 400, 1800 x 2800 Millimeter (mm)

- Click to view more

X

Double Roll Crusher Price And Quantity

- 1500000.00 INR/Unit

- 1 Unit

Double Roll Crusher Product Specifications

- 25 T/hr

- 400 x 400, 1800 x 2800 Millimeter (mm)

- Yes

- Yellow

- Mild Steel

- Stone Crusher

- Yes

- Stone

Double Roll Crusher Trade Information

- Cash Advance (CA)

- 1 Unit Per Month

- 1 Months

- All India

Product Description

Product details

| Minimum Order Quantity | 1 Piece |

| Available Size | 400 mm x 400 mm, 1800 mm x 2800 mm |

| Capacity | 25 TPH |

| Country of Origin | Made in India |

| Motor Power | 20 HP |

| Material | MS |

| Brand | VE |

| Frequency | 50 Hz |

| Feeding Size | 60 mm |

| Usage/Application | Industrial |

High-Capacity Stone Crushing

This double roll crusher processes up to 25 tons per hour, making it ideal for medium to large-scale stone crushing operations. Its advanced design, together with automated and computerized systems, boosts productivity while reducing manual intervention. Compatible with various stone sizes, it efficiently breaks down raw materials for further manufacturing or construction purposes.

Precision Engineering and Durability

Crafted from quality mild steel, the double roll crusher stands out for its robust construction. Its computerized automation enhances accuracy, while the automatic mechanisms minimize human error. The practical yellow color ensures equipment visibility and safety in busy work environments. These features combine to provide years of reliable service in heavy-duty applications.

FAQs of Double Roll Crusher:

Q: How does the double roll crusher operate automatically and what is the benefit?

A: The crusher employs computerized controls and automatic mechanisms to adjust rollers and manage feed rates. This automation ensures uniform crushing, consistent output, and minimizes operator intervention, making the process more efficient and reducing the risk of operational errors.Q: What types of stones can the double roll crusher handle?

A: This equipment is designed for versatile stone crushing, capable of handling a variety of stone types commonly used in construction, mining, and manufacturing sectors. Its robust mild steel rollers can process stones of varying hardness and sizes within the specified dimensions.Q: When should companies choose a double roll crusher over other crushing equipment?

A: Companies should opt for a double roll crusher when consistent product size, high throughput (up to 25 T/hr), and minimal dust generation are required. It is particularly effective for medium-hard to hard materials and applications where automated, low-maintenance crushing is essential.Q: Where is this double roll crusher typically installed?

A: The crusher is generally installed in stone processing plants, construction sites, or industrial manufacturing facilities throughout India. Its compact dimensions offer flexibility in location, making it suitable for both indoor and outdoor usage.Q: What is the process for maintaining this double roll crusher?

A: Routine maintenance includes checking the roller surfaces for wear, ensuring the lubrication system is functioning, and verifying the computerized controls. The durable mild steel construction makes regular upkeep straightforward, supporting long-term operational reliability.Q: How does computerized control improve the crushers usage?

A: Computerized control enhances the operational precision of the crusher by automatically adjusting variables such as roller speed and feed intake. This leads to optimized throughput, energy efficiency, and consistently sized output, streamlining the workflow for operators.Q: What key benefits does the double roll crusher offer for Indian manufacturers and suppliers?

A: Manufacturers and suppliers in India benefit from increased productivity, reduced labor costs, and improved safety due to automation. The durable mild steel build provides longevity, while the machines flexibility supports various stone types and site conditions.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email