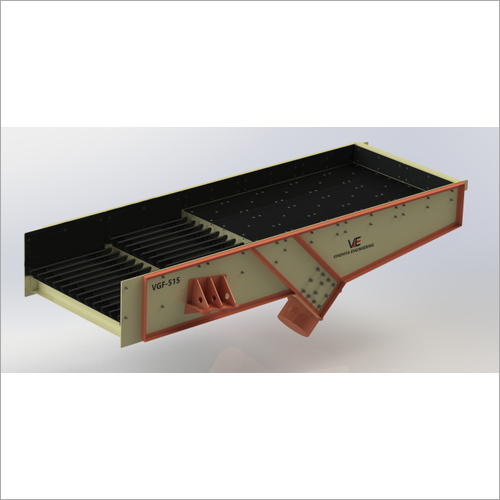

Vibrating Feeder Capacity 500 ton

Product Details:

- Color Yellow

- Material Other

- Condition New

- Capacity 150 Ton/day

- Power Mode Electric

- Voltage 380-440 Volt (v)

- Power Consumption 1 -10 Kilowatt (kW)

- Click to view more

Vibrating Feeder Capacity 500 ton Price And Quantity

- 250000 INR/Piece

- 1 , Piece

Vibrating Feeder Capacity 500 ton Product Specifications

- 380-440 Volt (v)

- Electric

- 50 Hertz (HZ)

- Industrial

- Yellow

- 150 Ton/day

- New

- 1 -10 Kilowatt (kW)

- Other

Vibrating Feeder Capacity 500 ton Trade Information

- Cash Advance (CA)

- 1 , Piece Per Month

- 1 Months

- All India

Product Description

The Cone Crusher Vcc 1050 is mainly used for secondary crushing and tertiary crushing in aggregate crushing of mines and quarries. Because of its strong crushing capacity and large output, it is more used for the crushing of medium-hard materials. The cutting-edge crusher technology has higher crushing efficiency and more convenient operation. Cone Crusher Vcc 1050 is a modified gyratory crusher. The essential difference is that the shorter spindle of the cone crusher is not suspended, as in the gyratory, but is supported in a curved, universal bearing below the gyratory head or cone. It is very efficient.

Product details

| Minimum Order Quantity | 1 Piece |

| Surface Finishing | Color Coated |

| Material | Cast Iron |

| Voltage | 380-440 V |

| Power Source | Electric |

| Power | 1-10 kW |

| Frequency | 50 Hz |

| Brand | VE |

| Feeding Speed | 50-60 feet per min |

| Usage/Application | Industrial |

| Capacity | 150 Tons |

Optimized Material Handling Efficiency

This vibrating feeder streamlines production processes by delivering consistent feed rates for bulk materials. Its advanced electric design ensures smooth operation with minimal manual intervention, boosting operational speed and allowing for precise control over input material.

Built for Heavy-Duty Industrial Use

Specifically engineered for rugged applications, the feeders durable yellow frame withstands harsh industrial conditions. Its 500-ton capacity and 150-ton daily throughput make it suitable for sectors like mining, construction, and material processing, delivering ongoing reliability.

FAQs of Vibrating Feeder Capacity 500 ton:

Q: How is the Vibrating Feeder installed in an industrial setup?

A: The Vibrating Feeder is typically mounted onto a stable base within your material handling operation. Installation requires standard electrical connections, matching its 380-440V voltage and 50 Hz frequency, and should be carried out by trained professionals to ensure optimal performance and safety.Q: What types of materials can this vibrating feeder handle?

A: This feeder is designed for a wide range of bulk materials, including aggregates, ores, coal, and other industrial raw materials commonly encountered in mining and manufacturing industries.Q: When is it recommended to use this feeder in production lines?

A: It should be used when consistent, controlled feeding of bulk materials is essential for continuous production processes, especially where handling high volumesup to 150 tons per dayis required.Q: Where is this product primarily used within industrial environments?

A: You will find this Vibrating Feeder in various areas, such as mining plants, aggregate processing facilities, and material transfer stations. Its durability and performance make it ideal for both primary feeding and more specialized industrial tasks.Q: What is the process for operating and adjusting this vibrating feeder?

A: After installation, operators can start the feeder by connecting it to its electric power source. Feed rates can be adjusted to match required material volumes, providing flexible control for different processing needs.Q: What are the benefits of choosing this particular feeder model?

A: Benefits include high-capacity handling, significant energy efficiency, durability in harsh environments, and reliable performance thanks to its robust construction and optimized electric components.Q: How does the power consumption of this feeder impact operational costs?

A: With a power consumption ranging from 1 to 10 kW, this feeder offers efficient operation, helping to minimize energy expenses while maintaining high productivity, which is essential for cost-effective industrial processes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+