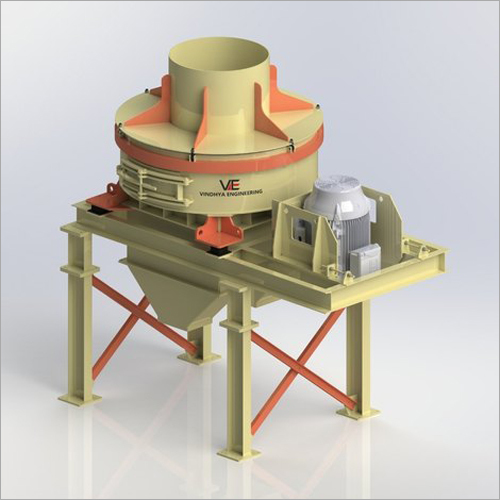

Stone Crushing Plants

Product Details:

- Product Type Jaw Crusher

- Material Mild Steel

- Capacity 50 T/hr

- Computerized Yes

- Automatic Yes

- Feature Crusher

- Color Yellow

- Click to view more

Stone Crushing Plants Price And Quantity

- 7000000 INR/Unit

- 1 Unit

Stone Crushing Plants Product Specifications

- Crusher

- Mild Steel

- Yes

- Yellow

- 50 T/hr

- Jaw Crusher

- Yes

Stone Crushing Plants Trade Information

- 1 Unit Per Month

- 2 Months

- All India

- ISO 2008

Product Description

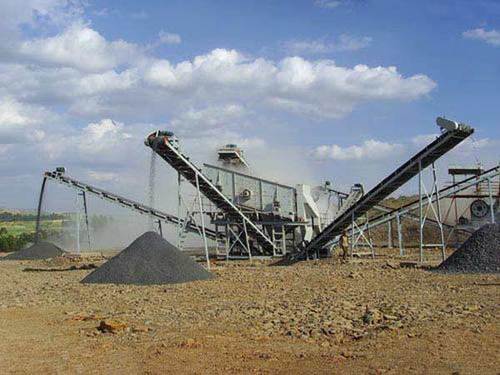

Product Description:The Stone Crushing Plants includes vibrating feeder, jaw crusher, impact crusher,vibrating screen, belt conveyor and centrally electric controlling system.

1.VIBRO GRIZZLY FEEDER 900 MM x 3000 MM :

With 80 mm Opening Grizzly Baars ,With , Motor Stand , V-Belt Rate . 260000/

2. JAW CRUSH 30"*24" :

Double Toggle Oil Lubricated , Double Wheel Chachise Stand, Power 50 HP , RPM 325/360 , Feed Size 22" 550 mm Production 80 TPH In 2.5"Material Size,Body MS Sail Plate Make "VINDHYA" , Model B2 , Rate 850000/

3.JAW CRUSH 36"*08" :

Double Toggle Oil Lubricated , Double Wheel, Chachise Stand Power 50 HP , RPM 385/400 , Feed Size 06" 150 mm , Body MS Sail Plate Make "VINDHYA" Rate. 850000/Each, Nog 2 1700000/-

Vibratory Screen 16"X05" :

4 Deck , Power 25 HP , Screen Sail ms Plate , Body 8 mm Plate Top 2 Screen 8 mm Plate , For Dust 4 mm Plate, Include Maintenance, Platform, Pully,v-belt Electrical Motor , Motor Stand, Weight 4500

Kgs. Nog 1 , Rte 420000/-

Conveyor Systems :

BC-1 Conveyor 900mm , Nog 1. ,BC-2 Conveyor 750mm, Nog 1. BC-3 Conveyor 600mm, Nog 1.Product Conveyor 450 mm Nog4.

Above all conveyors are including with drive pulley with rubber- lagging impact rollers, guide rollers , Toughing Idlers, return- rollers with J hook with motor g. box, conveyor

belt guide rollers , 570000/-

Hardware(Fastness,Rod Welding,Cutting,):INCLUDE

Gas cutting, welding rod, oxygen bottles , nut-bolts, Pedestals bearings, pulleys, couplings, colors, V belts Lpg bottles ,welding machine etc. Rate 300000/-

Erection and Commissioning :INCLUDE

With design drawings, supervision ,complete commissioning ,Erectioning on site. Rate 250000/-

Electricals with Cable Cabling Panel Board (L & T) : INCLUDE

- L & T Make Panel Board With Std. Attachments ,

- All Cables are ISI Mark, Earthing Complete ,

- as per Plant Design. Rate 400000/-

20 TON Steel (Angle, Channel , Gurder, Plates) INCLUDE

- FOUNDATION BOLTS, MATCHING PLATES,

- H- BEAM, PRIME PLATES, HEAVY STRUCTURE .

- Rate 920000/-

- We have successfully installed complete crushing units of capacity up to 300tph. We also provide skid mounted crusher machines for easy mobility.

Features:

- Hard wearing

- Longer service life

Technical Specification

|

Usage/Application |

Industrial |

|

Brand |

VE |

|

Material |

Mild Steel |

|

Capacity |

50 TPH |

|

Automation Grade |

Automatic |

|

Voltage |

380 - 440 V |

|

Power |

110 kW |

|

Frequency |

50 Hz |

Efficiency and Automation Combined

The stone crushing plant integrates computerized controls with automatic processes, ensuring minimal manual intervention and consistently high productivity. These features reduce downtime, optimize energy consumption, and maximize throughput, making the system ideal for fast-paced industrial environments.

Durable Mild Steel Construction

Built with high-grade mild steel, our yellow crushing plant withstands tough operational conditions. This material choice ensures longevity, minimal maintenance requirements, and continued reliability, which ultimately translates to lower operational costs for users.

Trusted Across India

As a leading manufacturer, supplier, and trader in India, we understand the diverse requirements of local industries. Our commitment to quality, timely support, and advanced engineering sets us apart, making us a preferred partner for numerous construction and mining projects nationwide.

FAQs of Stone Crushing Plants:

Q: How does the computerized and automatic system improve the stone crushing process?

A: The computerized and automatic system manages all operational parameters efficiently, maintaining consistent output, reducing human errors, and minimizing downtime. This results in a more streamlined and reliable stone crushing process.Q: What are the main benefits of using mild steel in the construction of this stone crushing plant?

A: Mild steel provides high durability, excellent resistance to wear, and requires minimal maintenance, making it ideal for heavy-duty applications like stone crushing. This ensures prolonged equipment life and cost-effectiveness.Q: When is a stone crushing plant with a 50 T/hr capacity most suitable?

A: A 50 T/hr capacity plant is best suited for medium to large-scale construction or mining projects that require continuous, high-volume stone processing. It provides the perfect balance between output and operational efficiency.Q: Where can this stone crushing plant be installed and used effectively?

A: This plant is designed for versatility and can be installed at construction sites, mining areas, or stone processing facilities anywhere across India. Its robust construction makes it suitable for both outdoor and industrial settings.Q: What is the typical process followed in operating this automated stone crushing plant?

A: Operators simply input processing instructions into the computerized console. The system handles stone feeding, crushing, sorting, and discharge automatically, ensuring smooth and efficient processing throughout.Q: How can users benefit from choosing a fully automatic, computerized stone crushing plant?

A: Users experience increased productivity, reduced labor costs, consistent product quality, and maximized safety due to decreased manual handling. The automation ensures reliability and greater control over the production process.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+